Water Based, Glossy Surface Polyurethane Shoe and Slipper Mold Release Agents

Water Based, Glossy Surface Polyurethane Shoe and Slipper Mold Release Agents

Introduction

Mold release agents play an important role in the production of polyurethane shoes and slippers. These release agents allow the molded polyurethane to come out of the mold easily and give the products the desired surface properties. Molds are usually made of aluminum, steel or specially coated metal alloys and the polyurethane material is poured into these molds. Mold release agents form a film when applied to the mold surface, reducing adhesion between the mold and the poured polyurethane material. While solvent- based release agents have been used for a long time, environmental and health restrictions have encouraged the development of water-based release agents. In this article, mold release agents for the slipper sole sector, which have a wide range of applications in polyurethane materials, and their types, water-based glossy sole release agents and Teknik Kimya's solutions in this field will be discussed.

Mold Release Agents Used in Slipper/Sole Industry

Slipper soles are generally produced with low density polyurethane raw materials. The choice of mold release agent is very effective for the polyurethane materials to be easily removed from the mold and to have the desired surface quality.

Mold release agents used in the Slipper/Sole industry are generally divided into two main categories: water- based and solvent-based. Solvent-based release agents generally offer good release performance and are easy to use. Solvent-based mold release agents can be produced with different solvents, allowing for more flexible use.

Water-based mold release agents are preferred for their environmentally friendly properties and low VOC (volatile organic compounds) content. Since the carrier media is water, it is non- flammable/non-flammable, which provides a safe working environment compared to solvent-based mold release agents. It is also a more economical solution as it can be diluted with water.

The surface properties of the final product produced from polyurethane material in the slipper/sole industry are characterized by many parameters. The produced soles may show matt or glossy properties. These characteristics vary according to the chemical properties of the release agent applied during the molding process.

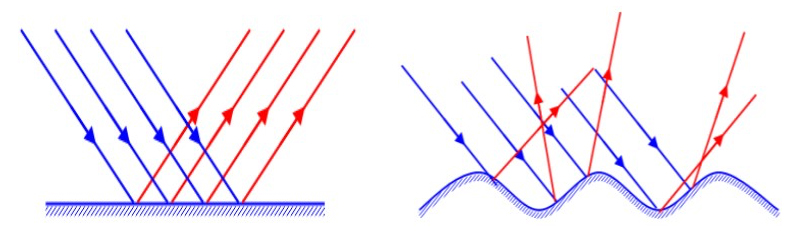

e gloss of a surface is related to how much and how the surface reflects light. Surface smoothness, interaction of light with the surface, surface treatments (polish, varnish applications, sanding, etc.) affect the reflection of light. Rays that are properly reflected from a material show the material brighter because they have a higher amount of light, while when the surface of the material is distorted, scattering increases and the material appears dull because the reflected light decreases.

Figure 1. Reflection of Light on Different Surfaces

Teknik Kimya's solutions developed for the slipper/shoe sole polyurethane sector spread well on the mold surface and form a smooth film, so that the produced slipper/shoe soles have a glossy surface feature.

Armaliz 30 – 1001 and Armaliz 30 – 1005 water based release agents have been developed for the slipper/sole sector. Provides balanced separation. Stable in the working environment, no phase separation is observed. The products are non- flammable, making the application environment safe. It is applied by spraying on the mold surface. Our products are available in ready-to-use and concentrated versions.

| Product | Properties |

|---|---|

| Armaliz 30 – 1001 | Ready-to-use, water-based mold release agent with a glossy surface developed for the sole/slipper industry |

| Armaliz 30 – 1005 | Water-based mold release agent with a concentrated, glossy surface developed for the sole/slipper industry |

Authors:

- Burak Güleş – Kalıp Ayırıcı Ürün Yöneticisi

- Arzu Aytimur – ÜRGE Uzman Yardımcısı